Plasterboard

Plasterboard is a versatile and lightweight construction material, widely used to create smooth surfaces for walls and ceilings, facilitating quick and efficient installations.

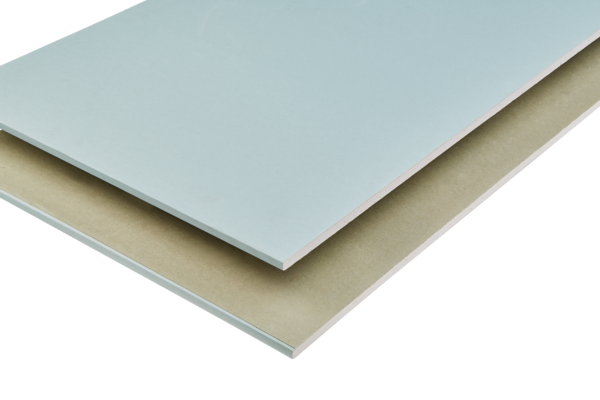

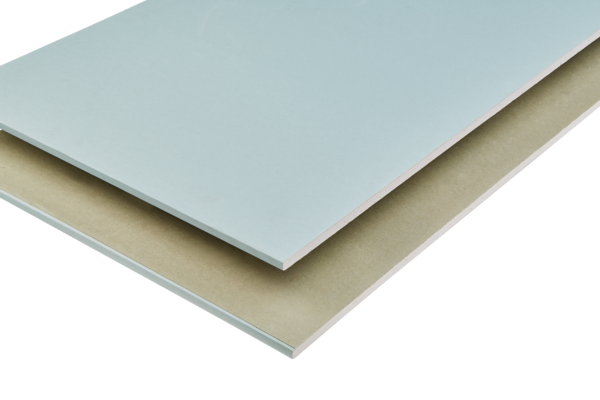

Gyproc Moisture Resistant Plasterboard protect bathrooms and kitchens from damage caused by high humidity.

Gyproc Moisture Resistant Plasterboard protect bathrooms and kitchens from damage caused by high humidity.

High moisture levels can lead to mould and staining, and could even cause structural damage. This moisture resistant board stops humidity getting in to ward off mould and help protect the structure of the build

Gyproc Moisture Resistant Plasterboard protect bathrooms and kitchens from damage caused by high humidity.

High moisture levels can lead to mould and staining, and could even cause structural damage. This moisture resistant board stops humidity getting in to ward off mould and help protect the structure of the build

Gyproc Moisture Resistant plasterboard protects walls and ceilings from high humidity, preventing damage in wet areas like kitchens and bathrooms.

High moisture levels can lead to mould and staining, and could even cause structural damage. This moisture resistant board stops humidity getting in to ward off mould and help protect the structure of the building.

Key facts

- Boards won't need to be replaced after exposure to high humidity

- Helps prevent structural damage caused by moisture

- Reduces the risk of mould and staining caused by moisture

- Achieves H1 water absorption according to EN 520

- Green paper lining for easy identification

Gypsum plasterboard with water repellent additives in the core and paper liners. Gyproc Moisture Resistant consists of an aerated gypsum core with water repellent additives encased in, and firmly bonded strong paper liners. Gyproc Moisture Resistant is a plasterboard that is suitable for drylining internal surfaces.

Plastering

Plastering should not normally be specified to Moisture Resistant and MR grade boards. These types of board are intended for use in environments of higher than normal humidity for which no gypsum plaster is designed to be suitable. Where moisture resistant board options are used in shell and core construction to provide temporary resistance to high moisture conditions, they can be skimmed at a later

date after the building envelope has been made weather-tight. Plaster should be applied only to the face of moisture resistant boards and pre-treatment with ThistleBond-it is required.

Gyproc FireLine is a fire resistant plasterboard that withstands fire for longer to allow for safe…

Gyproc FireLine is a fire resistant plasterboard that withstands fire for longer to allow for safe…

The board's excellent fire resistance rating makes it ideal for lining walls and ceilings in commercial spaces like offices and shopping centres, as well as in low rise housing and new build garages.

Gyproc FireLine is a fire resistant plasterboard that withstands fire for longer to allow for safe evacuation

The board's excellent fire resistance rating makes it ideal for lining walls and ceilings in commercial spaces like offices and shopping centres, as well as in low rise housing and new build garages.

Gyproc FireLine is a fire resistant plasterboard that withstands fire for longer to allow for safe evacuation.

The board's excellent fire resistance rating makes it ideal for lining walls and ceilings in commercial spaces like offices and shopping centres, as well as in low rise housing and new build garages.

Key facts

- Resists fire to allow for safe evacuation

- Pink paper facing for easy identification

Installation

Effect of temperature:

Start decorating as soon as possible after the finishing system is dry. Finish jointing systems with Gyproc Drywall Primer before painting.

Effect of condensation:

The thermal insulation and ventilation requirements of national Building Regulations aim to reduce the risk of condensation and mould growth in new buildings. However, designers should take care to eliminate all possibility of problems caused by condensation, particularly in refurbishment projects.

Cutting:

Either cut the board with a plasterboard saw, or score the front face paper with a sharp knife, snap it over a straightedge, then cut the back face paper. Cut holes for things like socket boxes using a utility saw.

Fixing:

Fix the board with the decorative side facing outwards to receive finishes. Install fixings at least 13mm from cut edges and 10mm from bound edges. Position cut edges at internal angles wherever possible. Stagger horizontal and vertical joints between layers by at least 600mm.

Jointing:

After fixing the board, start finishing it as soon as you can to limit the risk of damage or UV degradation to the paper liner. You can finish the board using jointing systems that comply with EN13963, including the Gyproc range.

Full-surface finishing:

After fixing the board, start finishing it as soon as you can to limit the risk of damage or UV degradation to the paper liner. You can finish the board using plaster that complies with EN13279-1, including the Thistle range.

Painting:

Start decorating as soon as possible after the finishing system is dry. Finish jointing systems with Gyproc Drywall Primer before painting.

Wallpapering:

Decoration should start as soon as practicable after the finishing system is dry. Jointing systems should be finished with Gyproc Drywall Sealer before application of wallcoverings.

Snagging and minor repairs:

For minor damage and dents, check that the board core isn't shattered. If it's intact, fill the damaged area with Gyproc EasiFill 60, allow it to set, then apply a second coat if you need to. When it's dry, sand it to a finish before redecorating the area.

For a damaged core, broken edges or extensive damage, repair and replacement procedures differ depending on the number of board layers and fire resistance of the system; please contact our Technical Support Team for specific advice.

Why are there so many different types of plasterboard? Roger explains.

Why are there so many different types of plasterboard? Roger explains.

Gypsum Plasterboard consists of a sheet of gypsum sandwiched between two layers of stout, specially processed paper. Gypsum Plasterboard was first manufactured in the UK over 90 years ago.

Why are there so many different types of plasterboard? Roger explains.

Gypsum Plasterboard consists of a sheet of gypsum sandwiched between two layers of stout, specially processed paper. Gypsum Plasterboard was first manufactured in the UK over 90 years ago.

What types of plasterboard are there?

Moisture-resistant plasterboard

In the core of moisture-resistant plasterboard are some additives which repel moisture. These plasterboards are the only suitable plasterboards for kitchens and bathrooms as the humid environment will otherwise decay the quality of the board over time and can result in loss of effectiveness of any insulating properties. Using non-moisture-resistant plasterboard in a moist area will lead to damp, rot and mould over time.

Buy from Wickes

Acoustic plasterboard

Opt for acoustic plasterboard and you’ll get additional benefits over just being able to finish off the room. Acoustic plasterboard will keep the sound out of the room and reduce how noise travels between rooms to give a more private and comfortable life for those living there. Utilising acoustic plasterboard in a living room refurbishment, for example, will mean that a loud movie won’t disrupt a quiet chat in the kitchen.

Buy from Wickes

Damp Proof Foil Backed plasterboard

Damp-proof plasterboard is equipped with a layer of foil attached to one side. It can be used in environments that are associated with an appreciable level of moisture (such as kitchens).

Buy from Wickes

Fire-resistant plasterboard

Fire-resistant plasterboard does exactly what it says on the tin. It’s important to become familiar with and choose the right fire performance rating as each rating denotes a different thing. Some fire-resistant plasterboard may be non-combustible, whereas some may offer 240 minutes of fire resistance before it will catch fire. If fire-resistant plasterboard isn’t specified and is just an optional extra, it’s worth choosing what suits your application best. If it’s specified then pick the correct performance rating to meet building regulations.

Buy from Wickes

Insulated plasterboard

Insulated plasterboard is a favourite amongst dry liners as it’s so easy to install. It’s essentially a piece of insulation board faced with plasterboard but the fact that they’re already bonded together and ready to go makes the process faster and more efficient than if you were installing a layer of insulation and then plasterboard. Just like regular plasterboard, this type can be finished without plastering over too.

Buy from Wickes

Info credit: https://www.insulationsuperstore.co.uk